Revolutionizing IIoT with Apache PLC4X

Who am I?

Your Name

Your role

Your email

What am I going to cover?

What is Apache PLC4X?

What can you do with PLC4X?

What could you do beyond that?

PLC4X is a set of libraries for communicating with industrial programmable logic controllers (PLCs) using a variety of protocols but with a shared API.

Apache PLC4X

Allows writing software for any type of PLC

When changing the PLC, only configuration needs to be adjusted

Strong growing number of supported protocols

Strong growing number of programming languages

Strong growing number of integration modules

Support of features, which protocols generally don’t support

Make PLC Data available in a unified way

PLC4X Supported Operations

Read

Write

Subscription

Cyclic

On Value Change

Event/Alarm

Discovery

Browse

PLC4X Supported Protocols

Siemens S7 (Step7)

Beckhoff ADS

Modbus (TCP/RTU)

EtherNet/IP

OPC-UA

Firmata

KnxNet/IP

CAN

ProfiNet

Allen-Bradley AB-ETH

Allen-Bradley DF1

BacNet

Emerson DeltaV

Luxtronic

Siemens S7 (TIA)

…

Polyglot PLC4X

Supporting multiple languages was planned from the start

The

Xin PLC4X stands for the multiple Languages

Writing PLC driver code is easy

Understanding the protocols is hard

As soon as a protocol is "understood", create drivers in many languages

Cross-compiling/wrapping just wouldn’t feel right

Heavy lifting done by our code-generation framework

What can you do with PLC4X?

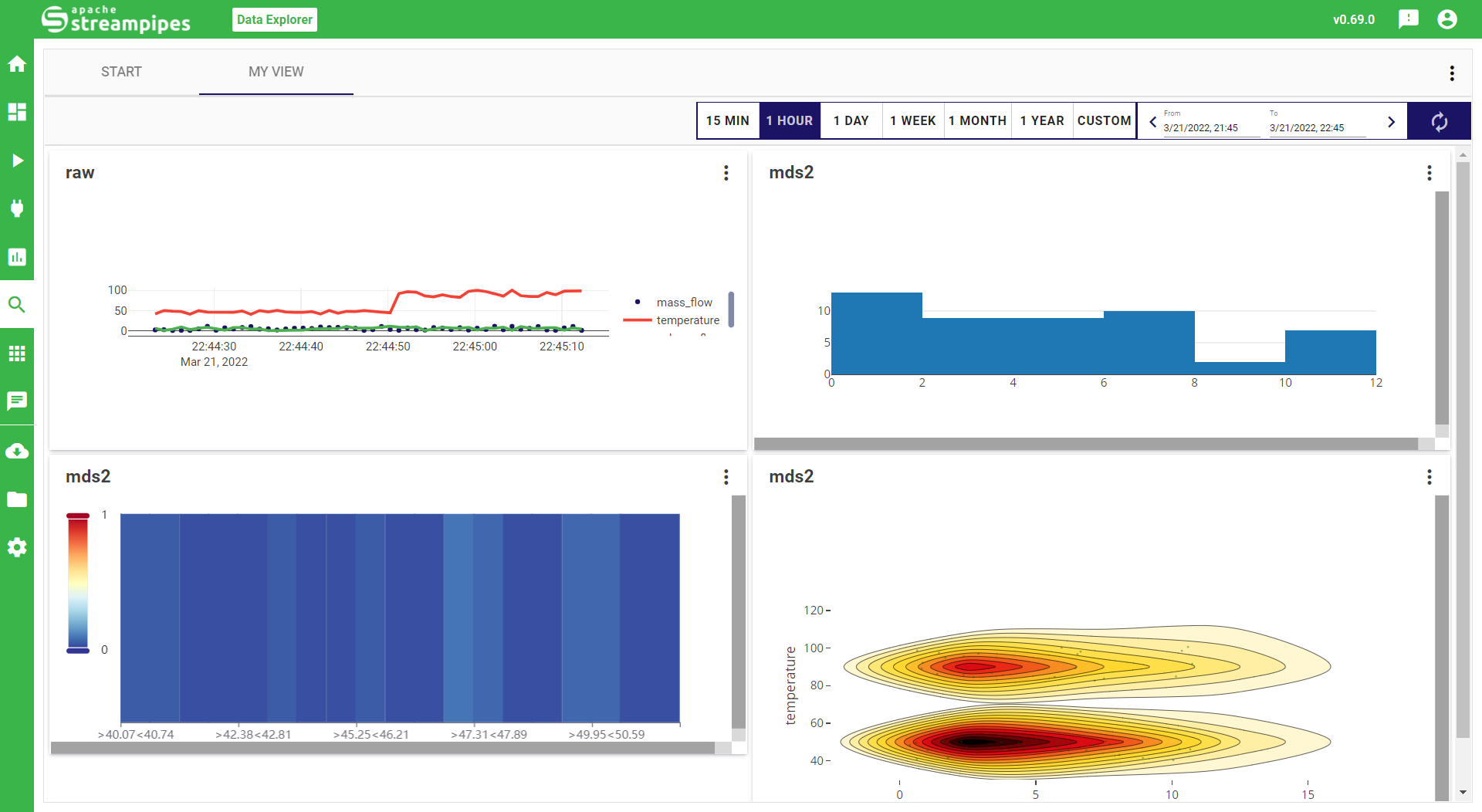

Making machine data visible

Overall Equipment Efficiency

Predictive Maintenance

Predict when a device needs maintenance

Predict probable failures

Run the machine at the right speed to minimize

Wear & tear

Energy-consumption

Resource usage

What could you do beyond that?

Following use-cases not yet fully implemented

From my experience, what the industry is really missing

Would need some extra work

PLC "Simulator" for unit-tests

In manufacturing engeineering almost no unit-testing done

If testing is done, then only on the real machine

Usually only happy-path testing

Solution:

PLC4X stand-alone application: "Simulator"

Built to speak with PLC4X drivers (Not full protocol support)

Use PLC4X to set values in the "PLC" from the Unit-Test

Test PLC4X Application against the simulator without needing real machinery

Historian

Historians are sort of ancient time-series databases

Mostly required for regulations

Extremely expensive

Don’t scale

Solution:

Use Apache PLC4X to get the data

Use Apache IoTDB to store the data

Add interfaces to replicate Historian interfaces

Digital Twin

Everyone is talking about Digital Twins

No good products available yet

Not expecting any OT-vendor product to be usable

Solution:

Use Apache PLC4X to get the data

Use Apache IoTDB to store the timeseries data

Use Eclipse Dito to store the current state

Use Apache KIE (incubating) to do smart things with the data

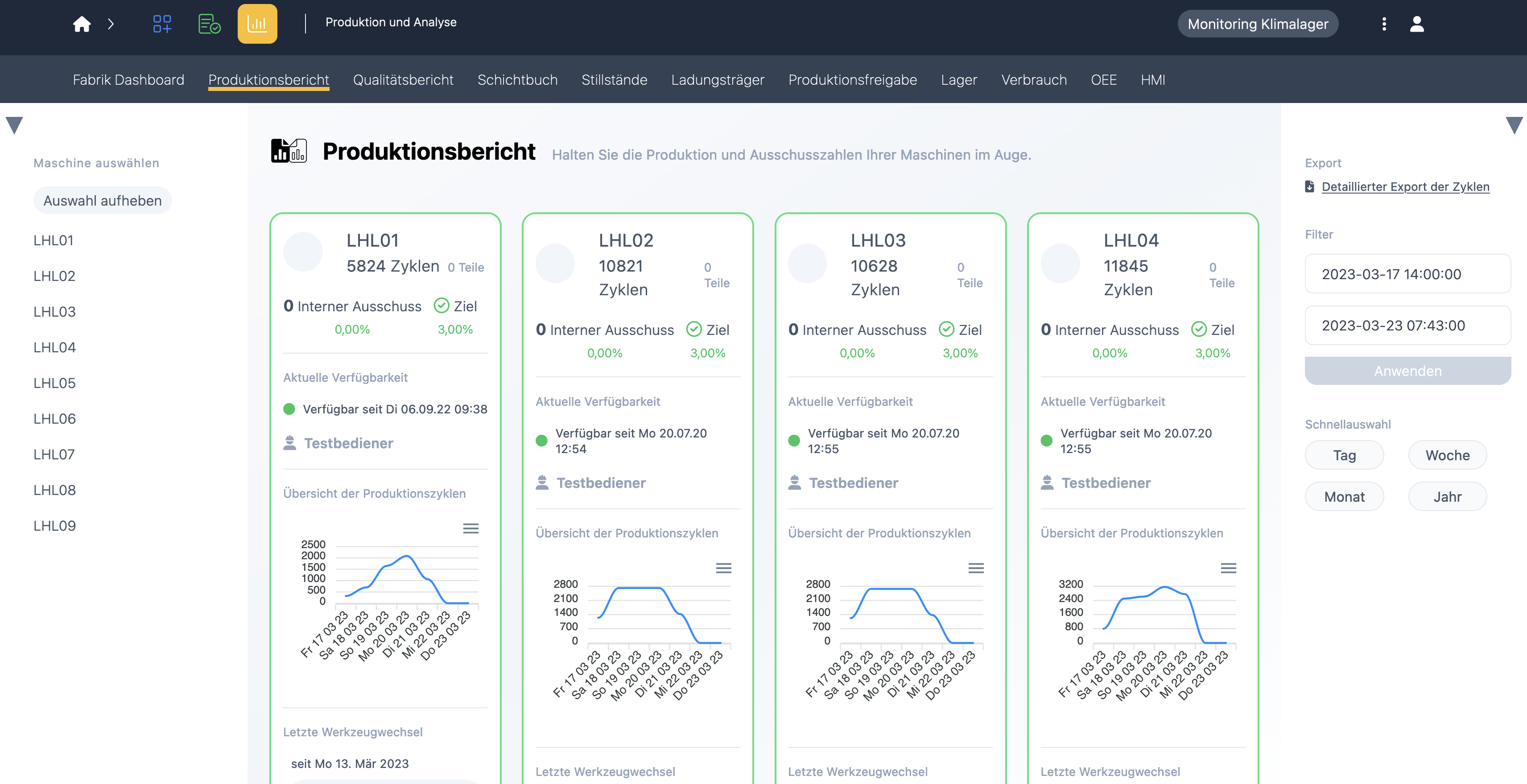

MES replacement

MES = Manufacturing Execution System

Big, fat, slow and don’t scale

Products today way more customizable:

A lot more interaction between PLC and MES needed

A lot more to do for the MES

MES becomes the bottleneck

Solution:

Building a distributed MES based on principle of highly scalable distributed systems

Want to make this happen?

Twitter: @ApachePLC4X